Case analysis of HMR casting high chromium forging

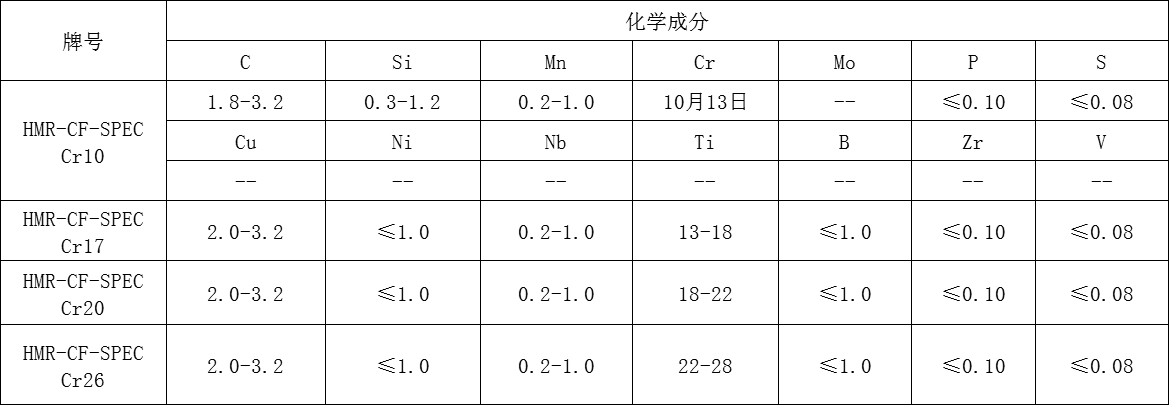

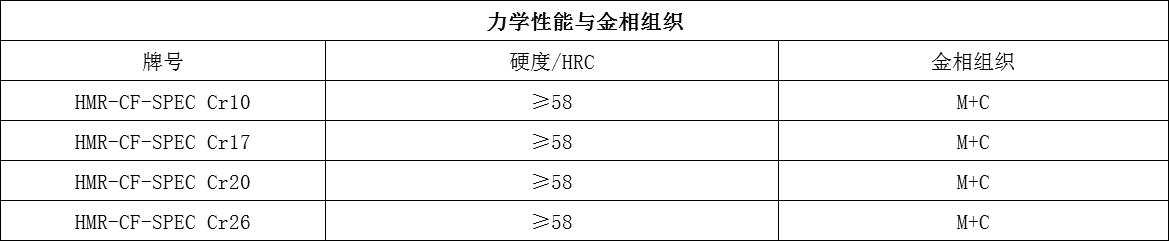

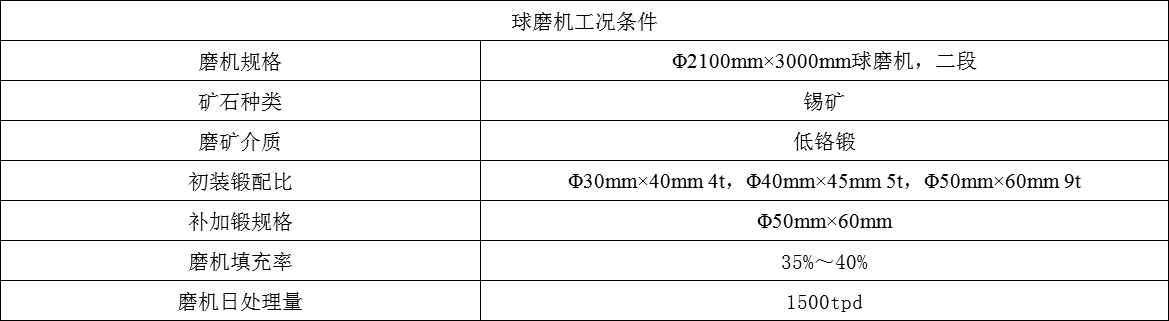

There are two series of grinding operation in a tin ore dressing plant in Yunnan. The two ball mills have the same specifications and the operation conditions are completely consistent. Series 1 adopts high chromium forging produced by HMR group, and series 2 adopts low chromium forging produced by other manufacturers.

Φ2100mm×3000mm球磨機

High chromium forging

After 1.5 months of operation, the results of statistical analysis on the use effect of HMR high chromium forging are as follows

The results show that the addition of high chromium forging for HMR casting is 180kg / D, and the wear is 0.137kg/t; the addition of low chromium forging for other manufacturers is 340kg / T, and the wear is 0.227kg/t, and the wear is reduced by 39.6%.

Compared with low chromium forging, high chromium forging of HMR casting has lower crushing rate, higher mill output and lower labor intensity.